Quality Control of Finished Lens

General

Both mineral (glass) and hard resin lenses are conformed to the following standards----ISO8980-1-1996, ISO14889-2003, GB10810-1996; hard resin lenses are also conformed to QB2506-2001 standard. Quality control system of the Seller has been approved according to ISO9002 (2000) standard. The Seller is giving 1-year limited warranty.

Material & Surface Shortcomings

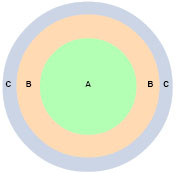

Each lens is divided into 3 zones as shown in the Carl Zeiss Master Plate.

| Lens Diameter | Zone A | Zone B | Zone C |

| 55mm | 30.0mm | 9.5mm | 3.0mm |

| 60mm | 30.0mm | 12.0mm | 3.0mm |

| 65mm | 35.0mm | 12.0mm | 3.0mm |

| 70mm | 40.0mm | 12.0mm | 3.0mm |

| 72mm | 45.0mm | 10.5mm | 3.0mm |

Carl Zeiss Master Plate

Cosmetic inspection is to be made by experienced inspectors based on Carl Zeiss Master Plate. The following table is only a recommendation to the inspectors since cosmetic inspection is totally subjective.

| 1st Quality Lens | 2nd Quality Lens | ||

| Scratch | Zone A | If width + 0.10mm, length + 2.00mm, 1 allowed. | If width + 0.30mm, length + 5.00mm, 2 allowed, but not centralized. |

| Zone B | If width + 0.15mm, length + 2.00mm, 1 allowed. | If width + 0.30mm, length + 7.00mm, 3 allowed, but not centralized. |

|

| Zone C | If width + 0.25mm, length + 5.00mm, 2 allowed, but not centralized. |

If width + 0.30mm, length + 10.00mm, 3 allowed, but not centralized. |

|

| Dots | Zone A | Not allowed. | If diameter + 0.20mm, 2 allowed, But not centralized. |

| Zone B | If diameter + 0.25mm, 1 allowed. | If diameter + 0.30mm, 3 allowed, But not centralized. | |

| Zone C | If diameter + 0.25mm, 2 allowed,but not centralized. | If diameter + 0.50mm, 3 allowed, But not centralized. | |

| Bubbles | Zone A | Not allowed. | Not allowed. |

| Zone B | Not allowed. | If diameter + 0.50mm, 1 allowed. | |

| Zone C | If diameter + 0.50mm, 1 allowed. | If diameter + 0.50mm, 1 allowed. | |

| Inclusions | Zone A | Not allowed. | Not allowed. |

| Zone B | Not allowed. | If diameter + 0.50mm, 1 allowed. | |

| Zone C | If diameter + 0.25mm, 1 allowed. | If diameter + 2.00mm, 1 allowed. | |

| Chips | Zone A | Not allowed. | Not allowed. |

| Zone B | Not allowed. | Not allowed. | |

| Zone C | If width + 0.50mm, length + 2.00mm, 1 allowed. | If width + 1.00mm, length + 3.00mm, 2 allowed, but not centralized. |

If without special notice, all lenses offered in this Purchase Direction are first quality lenses.

Power Testing & Marking

Power of each lens to be inspected and printed with Y&S Power Testing & Marking System. To avoid personal mistake, lens power to be tested with computerized lensmeter piece by piece, data will be transferred to computer automatically, then power and descriptions to be printed onto envelope by printer at the same time.

lens power to be tested with computerized lensmeter piece by piece, data will be transferred to computer automatically, then power and descriptions to be printed onto envelope by printer at the same time.

Drop Ball Test

Drop ball test to be made according to FDA 21CFR801.410 standard.

Random Check

Random check to be made referring to ISO2859, ISO3951 and GB2828 standards, parameters for the sampling are Level 2, AQL 4.0.

| Lot Size (Pieces) | Sample Size (Pieces) | Max. Rejection (Pieces) |

| 90 - 150 | 20 | 2 |

| 151 - 280 | 32 | 3 |

| 281 - 500 | 50 | 5 |

| 501 - 1,200 | 80 | 7 |

| 1,201 - 3,200 | 125 | 10 |

| 3,201 - 10,000 | 200 | 14 |

| 10,001 - 35,000 | 315 | 21 |